O.C. Sanitation to demo tech that kills ‘forever chemicals,’ turning waste into water, clean energy

What happens after you flush your toilet? For 2.6 million county residents, the answer to that question can be found at a 110-acre plant in Fountain Valley operated by the Orange County Sanitation District.

The industrial site, along with a similar setup in Huntington Beach, is where approximately 185 million gallons of sewage is treated in a complex process that essentially digests biologic material into its basic components.

Byproducts of that process include drinking water — about 130 million gallons per day, thanks to a groundwater replenishment system — methane gas and carbon dioxide, salt, nutrient-rich fertilizer that’s trucked off to commercial farms and a small amount of plastic, debris and grit that winds up in a landfill.

“People are using the water and, as I say euphemistically, are adding things into the water,” Assistant General Manager Rob Thompson said of the process in a recent interview. “Our job is to return that water to its pure state and recycle as best we can.”

It’s a messy job and one with a fairly significant environmental footprint. But for the past few years, Thompson and the district have been working to introduce a new technology that could change how the industry does its business.

A ‘game-changer’

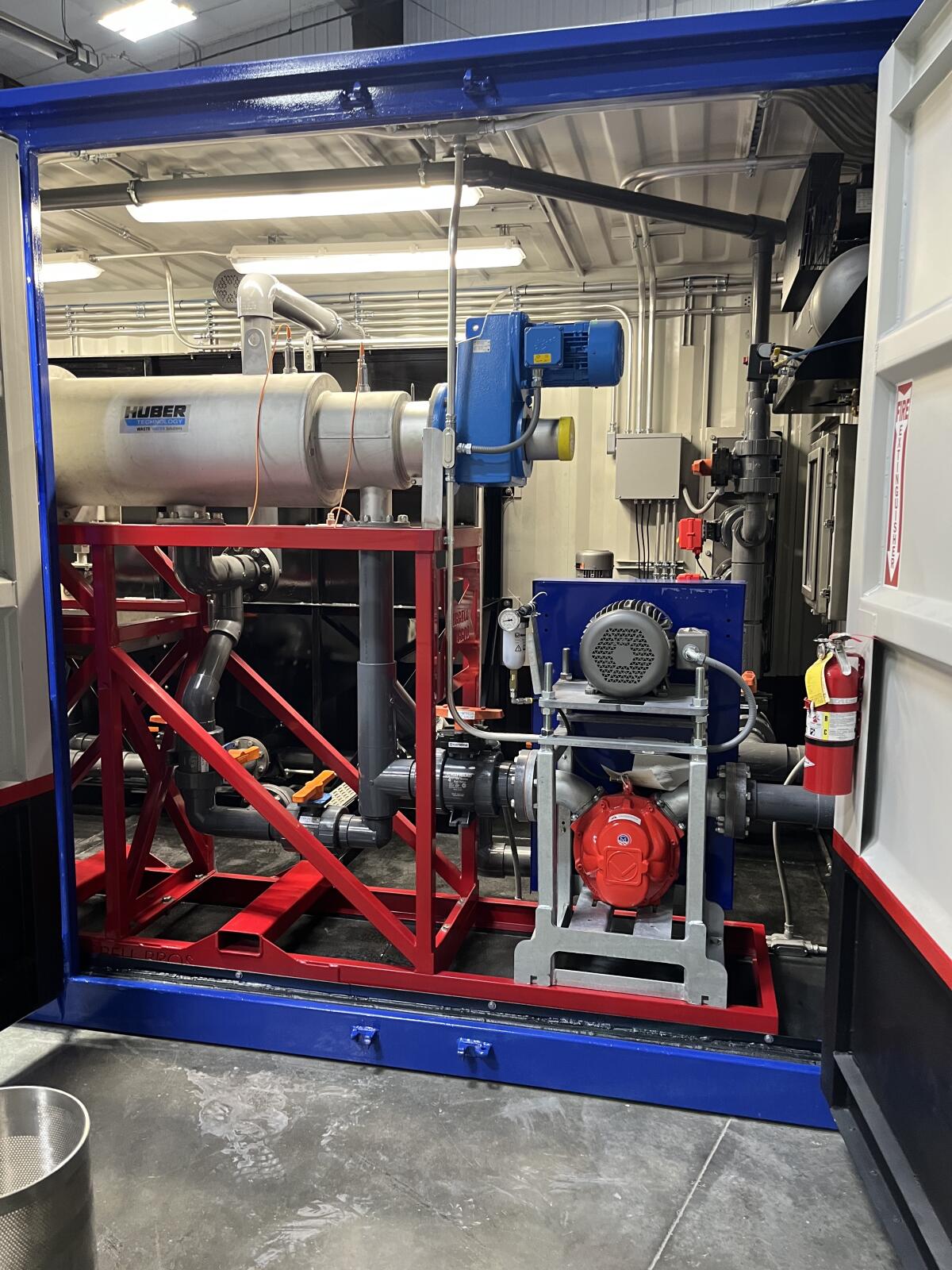

O.C. Sanitation officials have partnered with North Carolina-based cleantech company 374Water to bring a supercritical water oxidation unit, AirSCWO, capable of treating up to 6 tons of wet sludge per day, to the Fountain Valley facility as part of a demonstration project. The district’s board of directors approved the project in 2021 at a cost of $8.7 million.

Together, they aim to show how a new technology might be applied in a wastewater treatment setting and eventually scaled up over time, from a unit with a 6-ton capability to 30 tons to potentially 200 tons, the point at which two units could take on the district’s entire load.

“Six tons is a game-changer for the industry, because for a majority of treatment plants in America, that would be enough for them,” Thompson said during a recent tour of the Fountain Valley facility. “We’re trying to work our way to a 200-ton unit, which would turn into a game-changer for us.”

Unlike the current process, which is extremely labor and machine intensive, the new technology would ultimately have a much smaller physical footprint and an undeniably cleaner output, namely clean water and, at a large enough scale, electricity.

Biosolids, bacteria and viruses, even harmful PFAS — per- and polyfluoroalkyl “forever chemicals” used in consumer products like nonstick frying pans, stain-resistant rugs and cosmetics that do not easily degrade — would be transformed into benign minerals.

Gone would be the methane gas created by colossal anaerobic digesters that churn and burn sludge like giant stomachs, the energy required to run giant centrifuges that dewater wet sludge into 500 tons of digested solids daily and the string of 25-ton truckloads of fertilizer transported to commercial farms across the country.

“In 40 years, this could all be gone,” Thompson said.

How it works

The technology underpinning 374Water’s supercritical water oxidation units was created and later patented by Duke University civil and environmental engineering Prof. Marc Deshusses, who developed the process while responding to a “Reinvent the Toilet” challenge issued by the Gates Foundation.

Established in 2011, the call intended to find solutions for impoverished communities around the globe that suffered from a lack of safe sanitation.

Deshusses discovered when water is subjected to extremely high heat and pressure — above 374 degrees Celsius (705 degrees Fahrenheit) and 3,210 pounds per square inch — it enters a fourth “supercritical” state.

Neither a solid, liquid nor gas, it behaves differently, and organic materials are soluble, while inorganic materials are not, according to Doug Hatler, chief revenue officer for 374Water, the company launched in 2018 by Deshusses and fellow Duke engineer Kobe Nagar.

“When oxygen is mixed with the organic material under supercritical water conditions, an exothermic oxidation reaction occurs, breaking the carbon bonds and releasing a lot of heat,” Hatler explained Thursday.

“The organics are mineralized and there are no pathogens because nothing can survive at this pressure and temperature — so you wind up with clean water and minerals.”

The intense heat generated during the process can also be converted into electricity in larger units when a turbine is attached, meaning one day O.C. Sanitation could not only cease its methane production, but harvest clean energy.

Thompson, who’d formerly worked in chemical weapons disposal, read about Deshusses’ patent in a trade publication and reached out to 374Water to learn more about its applications in water treatment.

“I’d been following the physics of the process,” he recalled. “When I saw how this company was doing it, and how simplified it had become, it seemed it was much more possible. So, I gave them a call.”

A better mousetrap

The 6 ton-capacity unit to be installed at O.C. Sanitation’s Fountain Valley facility sometime this summer will be encased within two 40-foot shipping containers — one where the magic happens and the other containing a dewatering system that will thicken the sludge and feed it to the AirSCWO 6 unit.

Aside from the Board of Directors’ $8.7-million budget allocation, legislators U.S. Sen. Alex Padilla and Rep. Lou Correa (D-Santa Ana) in December announced they’d successfully earmarked $3.45 million in support of the project.

That announcement came roughly six months after the Environmental Protection Agency lowered the acceptable risk of PFAS in drinking water to near zero levels, associating human exposure with infertility, low birthweight and certain forms of cancer.

The agency invited states to apply for $1 billion under the new federal infrastructure law to address PFAS and other drinking water contaminants, the Associated Press reported in June.

In Fountain Valley, Thompson is hopeful the demonstration of the AirSCWO 6 unit could be a decisive first step toward a sea change in the industry.

“I think these guys have a great mousetrap, and I think it’s got a great likelihood of success,” he said. “It’s just a matter of getting the mousetrap right.”

All the latest on Orange County from Orange County.

Get our free TimesOC newsletter.

You may occasionally receive promotional content from the Daily Pilot.